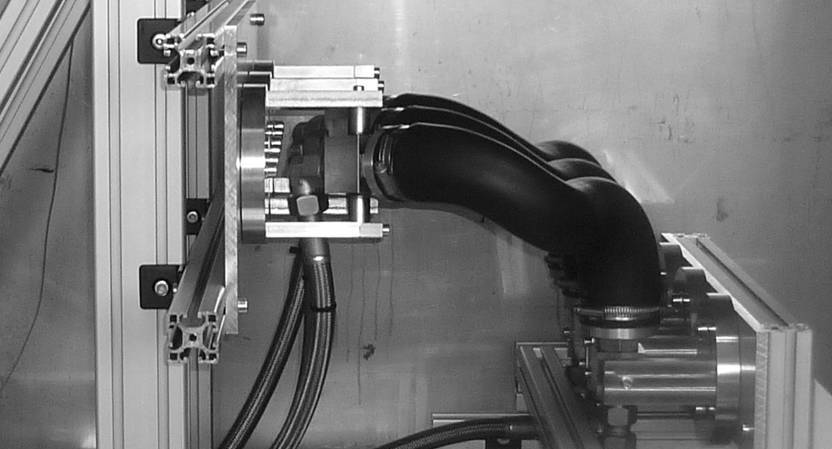

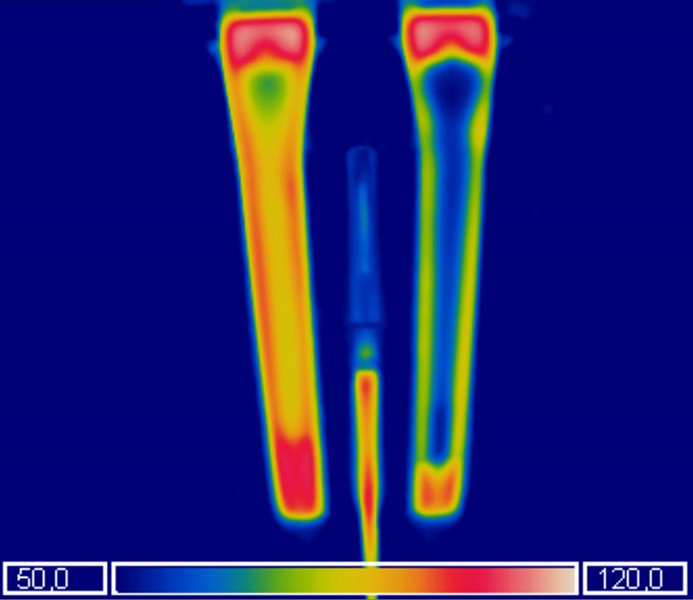

CO2injection technology (CO2 GIT) is a very interesting alternative to gas injection processes (GIT). In cooperation with Linde and Maximator, we adapted this technique for use in large volume production. The main benefits of this technology are the physical properties of CO2:

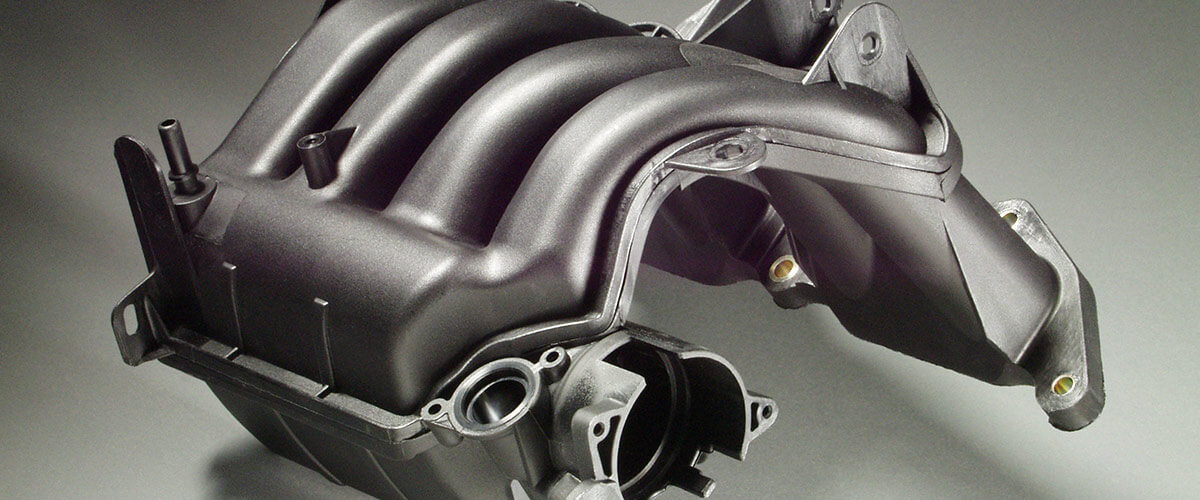

- Hervorragende Kühlwirkung

=> significantly reduced cooling times compared to nitrogen-based GIT

=> cycle times identical to or shorter than WIT - Absolute dry process, i.e.

– no drying / evacuation of parts required

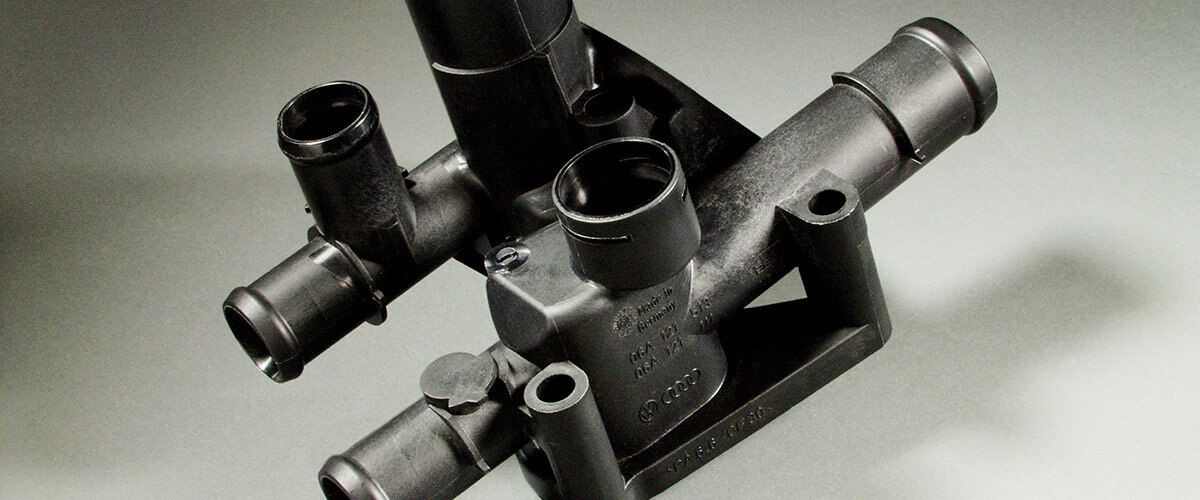

– conventional tool steel - Easy process control compared to water injection technology (WIT)

- The required GIT equipment is similar to that used for nitrogen injection

- No special materials required

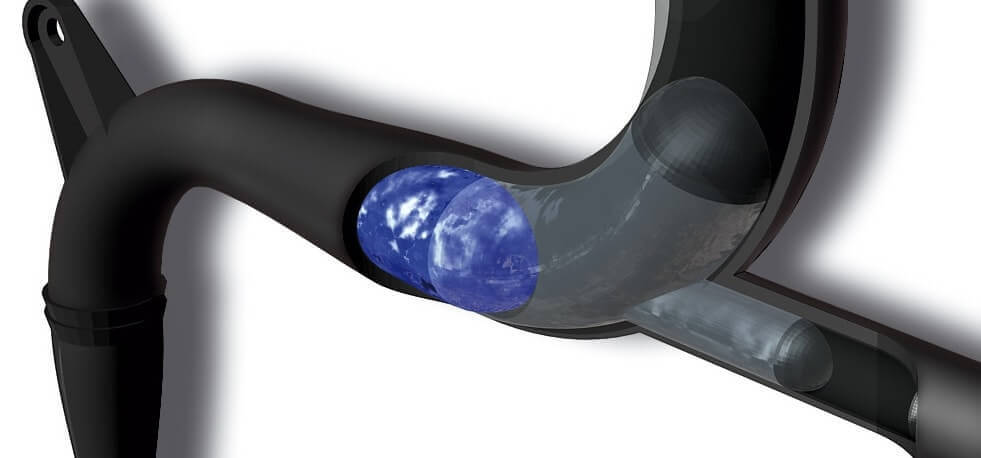

- Ideal for floating core processes (projectile injection technology, PIT)

Do you have an interesting FIT application? We will check its viability for CO2 GIT.